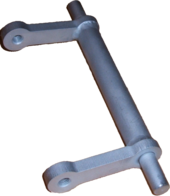

Large Pieces of Chrome/silver/aluminum Decorative Hardware

Decorative chrome plating on a motorcycle

Chrome plating (less commonly chromium plating) is a technique of electroplating a sparse layer of chromium onto a metal object. The product of chrome plating is called chrome. The chromed layer tin can be decorative, provide corrosion resistance, ease cleaning procedures, or increase surface hardness. Sometimes, a less expensive imitator of chrome may be used for artful purposes.

Process [edit]

Chrome plating a component typically includes these stages:

- Degreasing to remove heavy soiling

- Transmission cleaning to remove all residual traces of dirt and surface impurities

- Diverse pretreatments depending on the substrate

- Placement into the chrome plating vat, where information technology is allowed to warm to solution temperature

- Awarding of plating electric current for the required fourth dimension to attain the desired thickness

There are many variations to this process, depending on the type of substrate being plated. Different substrates need unlike carving solutions, such equally hydrochloric, hydrofluoric, and sulfuric acids. Ferric chloride is besides popular for the carving of nimonic alloys. Sometimes the component enters the chrome plating vat while electrically live. Sometimes the component has a conforming anode made from atomic number 82/tin or platinized titanium. A typical hard chrome vat plates at about i mil (25 μm) per hour.

Various finishing and buffing processes are used in preparing components for decorative chrome plating. The chrome plating chemicals are very toxic. Disposal of chemicals is regulated in most countries.

Some common industry specifications governing the chrome plating process are AMS 2460, AMS 2406, and MIL-STD-1501.

Hexavalent chromium [edit]

Hexavalent chromium plating, also known as hex-chrome, Crhalf-dozen+ , and chrome (Vi) plating, uses chromium trioxide (too known as chromic anhydride) as the principal ingredient. Hexavalent chromium plating solution is used for decorative and hard plating, along with bright dipping of copper alloys, chromic acid anodizing, and chromate conversion blanket.[1]

A typical hexavalent chromium plating process is: (one) activation bath, (ii) chromium bath, (3) rinse, and (4) rinse. The activation bathroom is typically a tank of chromic acid with a contrary electric current run through it. This etches the piece of work-piece surface and removes any scale. In some cases the activation step is done in the chromium bathroom. The chromium bathroom is a mixture of chromium trioxide (CrO3) and sulfuric acrid (sulfate, And thenfour), the ratio of which varies greatly between 75:1 to 250:1 by weight. This results in an extremely acidic bath (pH 0). The temperature and current density in the bath affect the effulgence and final coverage. For decorative blanket the temperature ranges from 35 to 45 °C (100 to 110 °F), but for hard blanket it ranges from 50 to 65 °C (120 to 150 °F). Temperature is too dependent on the current density, because a higher current density requires a higher temperature. Finally, the whole bath is agitated to go along the temperature steady and reach a uniform deposition.[1]

Disadvantages [edit]

One functional disadvantage of hexavalent chromium plating is low cathode efficiency, which results in bad throwing ability. This means it leaves a not-uniform coating, with more on edges and less in within corners and holes. To overcome this trouble the role may exist over-plated and ground to size, or auxiliary anodes may be used around the hard-to-plate areas.[i]

From a wellness standpoint, hexavalent chromium is the about toxic course of chromium. In the U.S., the Environmental Protection Agency regulates it heavily. The EPA lists hexavalent chromium as a hazardous air pollutant considering it is a human being carcinogen, a "priority pollutant" under the Make clean Water Act, and a "hazardous constituent" nether the Resources Conservation and Recovery Act. Due to its low cathodic efficiency and high solution viscosity, a toxic mist of water and hexavalent chromium is released from the bath. Wet scrubbers are used to control these emissions. The discharge from the wet scrubbers is treated to precipitate the chromium from the solution because information technology cannot remain in the waste product water.[1]

Maintaining a bathroom surface tension less than 35 dynes/cm requires a frequent cycle of treating the bath with a wetting amanuensis and confirming the effect on surface tension.[2] Traditionally, surface tension is measured with a stalagmometer. This method is, however, tedious and suffers from inaccuracy (errors up to 22 dynes/cm have been reported), and is dependent on the user's experience and capabilities.[3]

Additional toxic waste created from hexavalent chromium baths include pb chromates, which form in the bathroom because lead anodes are used. Barium is also used to control the sulfate concentration, which leads to the formation of barium sulfate (BaSO4).[1]

Trivalent chromium [edit]

Trivalent chromium plating, besides known as tri-chrome, Criii+ , and chrome (Three) plating, uses chromium sulfate or chromium chloride as the principal ingredient. Trivalent chromium plating is an alternative to hexavalent chromium in certain applications and thicknesses (e.g. decorative plating).[1]

A trivalent chromium plating procedure is similar to the hexavalent chromium plating procedure, except for the bath chemistry and anode composition. In that location are three principal types of trivalent chromium bathroom configurations:[i]

- A chloride- or sulfate-based electrolyte bath using graphite or blended anodes, plus additives to prevent the oxidation of trivalent chromium to the anodes.

- A sulfate-based bath that uses lead anodes surrounded by boxes filled with sulfuric acid (known as shielded anodes), which keeps the trivalent chromium from oxidizing at the anodes.

- A sulfate-based bath that uses insoluble catalytic anodes, which maintains an electrode potential that prevents oxidation.

The trivalent chromium-plating process tin can plate the workpieces at a similar temperature, charge per unit and hardness, every bit compared to hexavalent chromium. Plating thickness ranges from 0.005 to 0.05 mils (0.xiii to 1.27 μm).[one]

Advantages and disadvantages [edit]

The functional advantages of trivalent chromium are college cathode efficiency and better throwing ability. Ameliorate throwing power means better production rates. Less energy is required because of the lower current densities required. The procedure is more robust than hexavalent chromium because it can withstand electric current interruptions.[ane]

From a wellness standpoint, trivalent chromium is intrinsically less toxic than hexavalent chromium. Because of the lower toxicity it is not regulated equally strictly, which reduces overhead costs. Other health advantages include higher cathode efficiencies, which atomic number 82 to less chromium air emissions; lower concentration levels, resulting in less chromium waste and anodes that do not decompose.[ane]

One of the disadvantages when the process was outset introduced was that decorative customers disapproved of the color differences. Companies now apply additives to adjust the colour. In difficult coating applications, the corrosion resistance of thicker coatings is not quite equally good every bit information technology is with hexavalent chromium. The price of the chemicals is greater, but this is unremarkably offset by greater production rates and lower overhead costs. In general, the process must be controlled more closely than in hexavalent chromium plating, peculiarly with respect to metallic impurities. This means processes that are hard to control, such as barrel plating, are much more than difficult using a trivalent chromium bath.[ane]

Types [edit]

Decorative [edit]

Art Deco portfolio with chrome-plated cover, ca 1925

Decorative chrome is designed to be aesthetically pleasing and durable. Thicknesses range from 0.002 to 0.02 mm (two to 20 μm), yet, they are usually between 0.005 and 0.01 mm (5.0 and 10.0 μm). The chromium plating is usually applied over bright nickel plating. Typical base materials include steel, aluminium, plastic, copper alloys, and zinc alloys.[1] Decorative chrome plating is as well very corrosion resistant and is often used on car parts, tools and kitchen utensils.[ citation needed ]

Hard [edit]

Hard chrome , also known equally industrial chrome or engineered chrome , is used to reduce friction, better durability through abrasion tolerance and clothing resistance in general, minimize galling or seizing of parts, aggrandize chemical inertness to include a broader fix of conditions (such as oxidation resistance), and bulking material for worn parts to restore their original dimensions.[4] It is very difficult, measuring between 65 and 69 HRC (also based on the base metallic's hardness). Difficult chrome tends to be thicker than decorative chrome, with standard thicknesses in nonsalvage applications ranging from 0.02 to 0.04 mm (xx to 40 μm),[5] simply it tin be an guild of magnitude thicker for extreme wear resistance requirements, in such cases 0.1 mm (100 μm) or thicker provides optimal results. Unfortunately, such thicknesses emphasize the limitations of the process, which are overcome past plating actress thickness then grinding down and lapping to come across requirements or to amend the overall aesthetics of the "chromed" piece.[1] Increasing plating thickness amplifies surface defects and roughness in proportional severity, because hard chrome does not take a leveling event.[half-dozen] Pieces that are not ideally shaped in reference to electric field geometries (nearly every piece sent in for plating, except spheres and egg shaped objects) require even thicker plating to recoup for non-uniform degradation, and much of it is wasted when grinding the piece dorsum to desired dimensions.[ commendation needed ]

Modernistic "engineered coatings" practice not suffer such drawbacks, which often price hard chrome out due to labor costs lonely. Hard chrome replacement technologies outperform hard chrome in wear resistance, corrosion resistance, and toll. Rockwell hardness 80 is non boggling for such materials. Using spray deposition, uniform thickness that often requires no further polishing or machining is a standard feature of modern engineered coatings. These coatings are often composites of polymers, metals, and ceramic powders or fibers equally proprietary embodiments protected by patents or as trade secrets, and thus are usually known by brand names.[seven]

Hard chromium plating is subject field to dissimilar types of quality requirements depending on the application; for instance, the plating on hydraulic piston rods are tested for corrosion resistance with a salt spray test.[ citation needed ]

Automotive use [edit]

Most bright decorative items affixed to cars are referred to every bit "chrome", meaning steel that has undergone several plating processes to endure the temperature changes and weather that a auto is subject to outdoors (although the term and then passed on to cover whatever like-looking shiny decorative machine parts, including silvery plastic trim pieces in casual terminology). Triple plating is the about expensive and durable procedure, which involves plating the steel first with copper and then nickel before the chromium plating is applied.

Prior to the application of chrome in the 1920s, nickel electroplating was used. In the brusque production run prior to the United states entry into the Second World War, the government banned plating to save chromium and motorcar manufacturers painted the decorative pieces in a complementary color. In the concluding years of the Korean State of war, the US contemplated banning chrome in favor of several cheaper processes (such as plating with zinc and so coating with shiny plastic).

In 2007, a Brake of Hazardous Substances Directive (RoHS) was issued banning several toxic substances for employ in the automotive industry in Europe, including hexavalent chromium, which is used in chrome plating. Withal, chrome plating is metal and contains no hexavalent chromium afterward it is rinsed, so chrome plating is non banned.

Arms employ [edit]

Chrome-lining protects the barrel or chamber of arms from corrosion and makes these parts also easier to clean, but this is non the main purpose for lining a barrel or chamber. Chrome-lining was introduced in machine guns to increase the habiliment resistance and service life of highly stressed arms parts similar barrels and chambers, assuasive more rounds to exist fired before a barrel is worn and needs to be replaced. The end of the chamber, freebore and leade (the unrifled portion of the barrel simply forward of the bedchamber), equally well as the first few centimeters or few inches of rifling, in rifles are subject to very high temperatures — as the free energy content of rifle propellants can exceed 3500 kJ/kg — and pressures that tin can exceed 380 MPa (55,114 psi). The propellant gases act similarly as the flame from a cutting torch, the gases heating up the metal to red-hot land and the velocity tearing away metal. Under slow fire conditions, the afflicted areas are able to absurd sufficiently in between shots. Under sustained rapid fire or automatic/cyclic fire there is no time for the heat to dissipate. The heat and pressure furnishings exerted past the hot propellant gasses and friction past the projectile can quickly cause impairment by washing away metal at the terminate of the chamber, freebore, leade and rifling. Hard chrome-lining protects the sleeping room, freebore, leade and rifling with a thin coat of wear resistant chrome. This significantly extends barrel life in arms that are fired for prolonged periods in full-car or sustained rapid burn modes. Chrome-lining has a negative effect on the maximum achievable accuracy of barrels.[8] Some arms manufacturers use Stellite-lining blend every bit an alternative to hard chrome-lining to further increase the clothing resistance and service life of highly stressed artillery parts.[ix] [10]

See also [edit]

- Stainless steel

- Metal toxicity

References [edit]

- ^ a b c d e f grand h i j g fifty m Pollution Prevention Engineering science Profile Trivalent Chromium Replacements for Hexavalent Chromium Plating (PDF), Northeast Waste Direction Officials' Association, 2003-x-18, archived from the original (PDF) on 2011-07-20.

- ^ "Archived re-create". Archived from the original on 2010-11-30. Retrieved 2010-08-twenty .

{{cite spider web}}: CS1 maint: archived re-create as title (link) - ^ "Surface Technology Environmental Resources Center - STERC". Archived from the original on 2010-07-07. Retrieved 2010-08-20 .

- ^ "QQ-C-320B" (PDF). everyspec.com. Archived (PDF) from the original on 16 August 2017. Retrieved three May 2018.

- ^ "Pattern Recommendations For Difficult Chrome Plating". U.S. CHrome Corporation. Archived from the original on 2017-08-16. Retrieved sixteen Baronial 2017.

- ^ Degarmo, E. Paul; Black, J T.; Kohser, Ronald A. (2003), Materials and Processes in Manufacturing (ninth ed.), Wiley, p. 793, ISBN0-471-65653-4 .

- ^ Vernhes, Luc (2013). "Alternatives for hard chromium plating: Nanostructured coatings for severe-service valves". Materials Chemical science and Physics. 140 (two–iii): 522–528. doi:ten.1016/j.matchemphys.2013.03.065.

- ^ Chrome-lined Barrels and Chrome-plated Components

- ^ Stellite Lined Barrels

- ^ Torture Test: U.S. Ordnance MAG-58/M240 – Small Arms Defense force Journal - Dan Shea - 28 February 2013

Farther reading [edit]

- SAE AMS 2406

- SAE AMS 2438

- SAE AMS 2460 - Plating, Chromium

0 Response to "Large Pieces of Chrome/silver/aluminum Decorative Hardware"

Post a Comment